Shop Startpage Guitar Making Techniques Tonewood Cutting Wood

Cutting Wood

Here I would like to talk about the cutting of the logs.

If the wood is cut, the best possible compromise must be made between high-quality raw tonewood and the equally expensive waste wood.

The following questions arise:

- How do I divide a geometric cylinder into such pieces that I can use them for my purpose?

- For which instrument do I need which wood? Do I make violins, cellos, double basses, guitars, lutes, etc.? Each instrument needs certain standard measurements and since I am of course not a jack of all trades on all instruments, I have to focus on certain measurements. If there are leftovers, I have to know into which dimensions I can cut further, maybe some smaller wood can be sold further?

- What machines, possibilities can be used for further processing?

Theoretical geometry:

Tonewood for sound production is optimally cut when the thinnest possible wood has the highest possible stiffness. This is the case when there are only standing annual rings in the tops, backs and sides. One speaks of standing annual rings when the annual rings run parallel to the narrow outer surface (or at right angles to the wide one). The aim of clay wood extraction must be to obtain as many usable sections as possible from one log diameter. The following are some theoretical considerations.

If I use a log section and try to make only guitar tops as boards and wedges for jazz guitars, nesting attempts bring such results:

|

|

If you divide the log into 60 wedge pieces of 6° each and take into account about 2cm of edge layer not to be used and 8cm of core, the log must be 85cm thick in the left case and 88cm thick in the right case (30 boards and 30 wedges)!

|

In the above optimization you already get 34 wedges and 32 boards with a diameter of 75cm.

|

With a diameter of 60cm, one could produce 36 pieces of neck scantlings with horizontal annual rings and 12 with vertical annual rings.

Of course, I am aware that there is no wood of such quality that I could plan the cutting on the drawing board, but the occupation with the matter brought me a little further in the planning of the sawing jig. What angles and what thicknesses need to be cut?

Standard dimensions for tone wood:

The dimensions below refer to dry dimensions! It is essential to note that the drying process causes the wood to shrink. Each type of wood has special values for the dimensional changes. Franz Jahnel gives the following values:

| Species | radial % | tangential % | along % | Volume |

| Spruce | 3.6 | 7.8 | 0.3 | 4.1 |

| Sycamore | 5.0 | 8.0 | 0.4 | 5.0 |

| Jacaranda | 5.3 | 9.9 | 0.4 | 6.3 |

| mahogany | 2.4 | 4.4 | 0.1 | 1.4 |

| Ebony | 3.1 | 6.5 | 0.2 | 3.1 |

- ** radially: along the radius

- * tangentially: along the years ring

- *** along: length along the trunk

Usual tone wood dimensions:

| Guitar (Classical) | Top / Bottom | 2 pieces 530 x 190-200 x 4-5 |

| Sides | 2 pieces 800 x 110 x 3 | |

| Fretboard | 500-510 x 60-70 x 8-9 | |

| Neck blank | 650 x 80 x 25 | |

| Guitar (Western) | Top / Bottom | 2pieces 560 x 215 x 5 |

| Sides | 2 pieces 850 x 125 x 4 | |

| Fretboard | 700 x 76 x 8 | |

| Neck blank | 650 x 80 x 80 | |

| Guitar (jazz) | Top / Bottom | |

| Sides | ||

| Fretboard | ||

| Neck blank | ||

| Guitar (electric) | Cap strips | 2pieces 500 x 190 x 10-20 |

| body | 2pieces 500 x 190 x 52 | |

| Neck block | 700 x 100 x 26/30 | |

| Fretboard | 500 x 75/55 x 8 | |

| Bass (E-) | Fretboard | 45/70 x 730 (4-String) |

| 52/85 x 730 (5-string) | ||

| 60/97 x 730 (6-string) | ||

| Cap strips | 2 pieces 550 x 190 x 10-20 | |

| body | 550 x 190 x 45/52 2 pieces | |

| Neck block | 870 x 110 x 26/30 | |

Splitting or sawing?

As mentioned at the beginning, good tonewood must have as many "standing annual rings" as possible. This is actually not quite correct. Often, it only refers to the easily visible cross-sectional area at the saw cut. More precisely, the annual ring must also be perpendicular to the third dimension (depth), i.e. it must extend straight through the entire board.

If you imagine the log as a bundle of straws (cells of the wood structure look simplified like this), you have to try to get the boards in such a way that as few straws as possible are cut laterally.

In wood with standing annual rings, you can see the "medullary mirror", which is particularly desirable in spruce. If you look at a finished instrument with a spruce top against the light, you can see if one of the mirrored halves of the top appears slightly darker than the other if you tilt the guitar slightly backwards. This is a sure sign that the top has been sawn. The different darker the halves appear, the more cell fibers ("straws") have been cut. If you choose raw tonewood for a blanket, you can find out something similar from the bending resistance of the board. If a board can be bent more easily than other boards with the same grain, important wood fibers have been cut - it is better to take the stronger one.

So much for the introduction of splitting or sawing.

Most optimal tone wood is split, because it separates on the cell walls. Now remember the last wood chopping. Spruce is easy to split, but maple!? In hardwoods, it is agreed that good eye in sawing is enough to get good tone wood. Spruce logs are best pre-split and then further separated on the saw.

The more manual work that goes into the finishing process, the more expensive the product will be. This is also the reason why mostly industrially produced tonewood is almost exclusively sawn. It is faster and cheaper to first cut the log into quarters or eighths along its entire length than to first cut the log into 50-65cm pieces, then split them, and then saw the quarters or eighths into small pieces.

|

|

Here you can see the splitting of a spruce section.

|

|

|

|

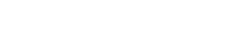

Here's what my logs looked like when I sawed them:

|

|

|

|

These quarter and eighth logs must now be cut to rough lumber length. I mostly cut to 650 and 900mm length.

|

|

|

|

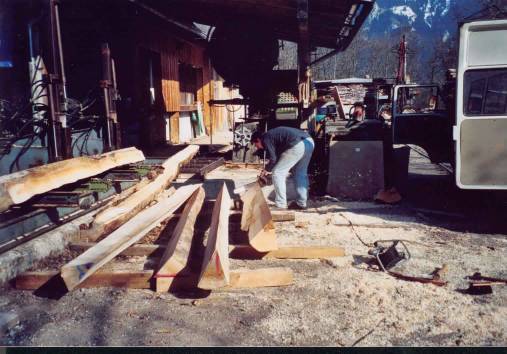

If the wet spruce wood is not further processed within the next 2-3 days, it starts to crack at the end faces. This is due to the fact that the cells are open at the end faces and more moisture can be released here. As a result, the wood dries unevenly and stress cracks appear. These can be avoided by either storing the wood in a cool, moist place or by sealing the end faces. For this purpose, there can be professional polyester compounds in dispersion, much easier and cheaper are latex paint residues or cheap white glue.

Maple is not so critical here. If you put it on the front surface for a few days, the water "runs out". Here again, care must be taken that the end surfaces do not begin to falter and rot and discoloration penetrate the wood.

|

|

|

|

Processing on the band saw:

I processed the log sections on a normal joiner's band saw. This had a roller diameter of 600mm and was driven by a 2.2kW motor. I built a variable fence so that I could set different angles and thicknesses. Using markings on the saw and the fence, I could set the desired thickness or angle from cut to cut.

The saw blade was 30mm wide and very strongly set to transport the wet chips away well. The saw blade was sharpened a total of 3x during this time!

With great force, the sections must be placed on the table. With moderate force, the wood must be pressed against the fence and the saw blade.

The large log quarters had a weight of a good 50-60kg!

What I could not believe at first: Maple can be processed many times better than the much lighter and softer spruce wood! The reason is that spruce chips have much more resin which clogs the saw blade, smearing it and thus greatly hindering chip transport. About every hour the saw blade had to be cleaned from the resin with a special agent (please put on hemp shoes and glasses - not exactly healthy that stuff!).

|

|

|

|

My opinion from today's perspective on band sawing:

- The drive motor was actually too weak, 4 or 7 Kw at hand feed are much better. At cutting depths of a little more than 30cm (!) in hardwood, a normal saw is quickly overloaded. I built an inside/outside thermometer with the outside sensor between the cooling fins of the motor on the saw. This way I could always see how much load the motor was under and could take a break if it got too hot. By the way, you could also tell by the temperature how the sharpness of the blade was dropping! It is also important to check that the motor ventilation is optimal.

- The roller diameter should also be larger, as it is then possible to use a 40-50mm wide saw blade. Wider saw blades do not run as much. In fact, the blunter the saw became, the more the baltt ran and the wood block had to be visibly trued.

- The blade guide must always be well greased and oiled, otherwise it will break.

- A machine feed makes the work much easier