Tools, parts and what you need for guitarmaking

-

Tools & Jigs

-

Tools

- Fretting Tools (Base)

- Pliers

- Sanding Blocks

- Brushes

- Files

- Routers

- Routing Templates

- Templates / Straight Edges

- Fretting Templates - Fret Scale Templates

- Clamps

- Knives

- Measuring Tools

- Tool Sets

- Reamer

- Keys, Wrenches

- Drill Jigs

- Saws

- Drill Bits

- Scrapers

- Bending Irons

- Other Tools

- Fret Hammer

- Fret Pressing

- Fretboard Protector

- Fret Bender & Tang Nipper

- ... More

- Jigs for Luthiers

-

Tools

-

Hardware & Parts

- Necks & Bodies

- Tuners

-

Hardware / Parts

- Truss Rods

- Carbon / Titan Reinforcement

- Trussrod Nuts

- Washer for truss rods

- Bridge Pins

- End Pins

- Bridges & Tailpieces E-Guitar

- Bridges & Tailpieces

- Covers

- Pickguards / Scratch Plates

- Strap Locks

- Bridge Accessories / Spare Parts

- Screws, Nuts, Washers

- Neck Attachement

- String-Ferrules

- Jack plates

- Control Plates

- String Retainer / String Trees

- knobs (pots/switch)

- Relic Parts

- ... More

- Nuts & Saddles

- Fret Wire

- Pickups & Electronics

- Materials & Supplies

- How-to

- Guitar Making

Shop Startpage Guitar Making Luthiery 000-Standard Bridge

Preparation of the Bridge

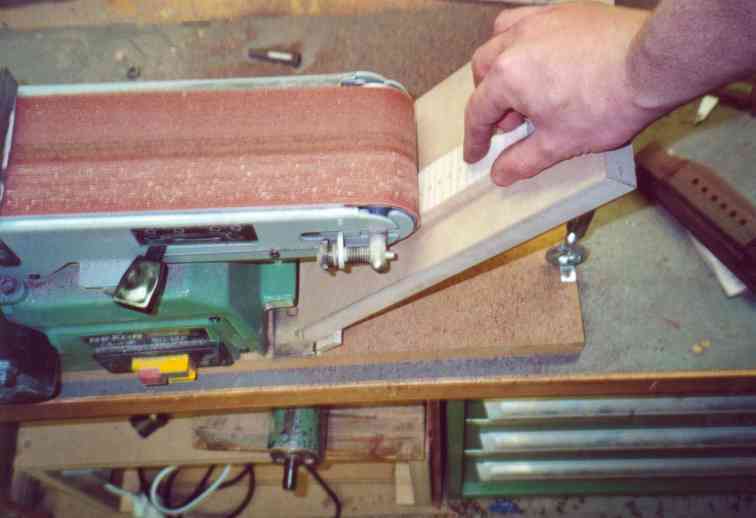

For the bridge you need a narrow piece of hardwood with standing annual rings. Usually rosewood is used, but flamed maple makes an equally good bridge. First I made a wooden template, drew the outlines on the piece of wood and sawed them out.

|

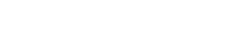

I grind the "ears" with a belt sander to 5mm thickness.

|

|

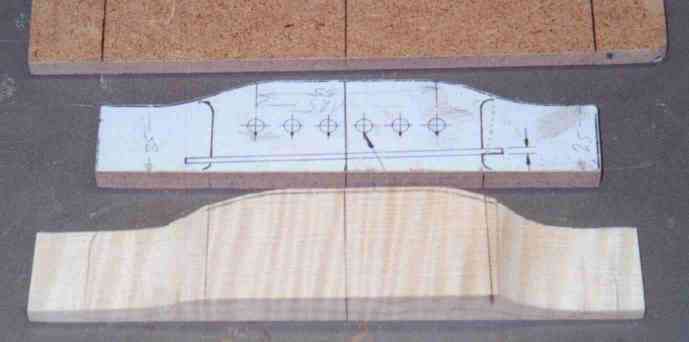

The position of the string holes are marked and made with a sharp drill.

|

|

Radii are applied to the upper side with the top milling cutter and a starting milling cutter..

|

|

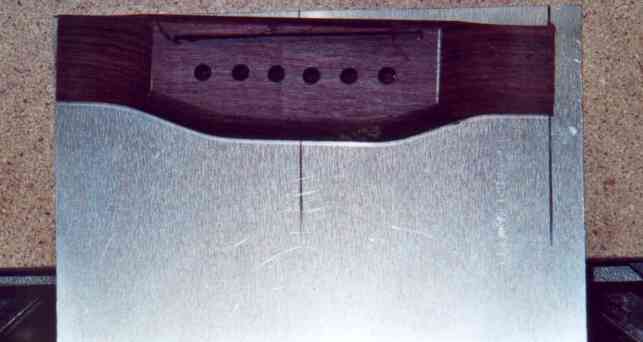

Now the channel for the bar insert must be milled. For this I glue the blank with carpet tape on an aluminium sheet. It is fixed diagonally so far that the channel runs parallel to the front surface of the sheet (6.5mm to 65mm).

|

|

|

|

A finger cutter with a diameter of 2.5mm creates the canal. The sheet metal including the bar blank is moved along a strip, the stop on the left and right side is fixed with a screw clamp.

|

Now the upper side must be created with a rasp or file.

|

With a buffing wheel and some buckhorn wax the almost finished bridge is polished.

|

|

|

|

|

Rall Guitars & Tools Hauptstrasse Tel +49 (0) 8803-48856-56 Retail Shop: By appointment only |

Subscribe our Newsletter By subscribing our newsletter you accept our Privacy Policy and Terms and Conditions. |