Tools, parts and what you need for guitarmaking

-

Tools & Jigs

-

Tools

- Fretting Tools (Base)

- Pliers

- Sanding Blocks

- Brushes

- Files

- Routers

- Routing Templates

- Templates / Straight Edges

- Fretting Templates - Fret Scale Templates

- Clamps

- Knives

- Measuring Tools

- Tool Sets

- Reamer

- Keys, Wrenches

- Drill Jigs

- Saws

- Drill Bits

- Scrapers

- Bending Irons

- Other Tools

- Fret Hammer

- Fret Pressing

- Fretboard Protector

- Fret Bender & Tang Nipper

- ... More

- Jigs for Luthiers

-

Tools

-

Hardware & Parts

- Necks & Bodies

- Tuners

-

Hardware / Parts

- Truss Rods

- Carbon / Titan Reinforcement

- Trussrod Nuts

- Washer for truss rods

- Bridge Pins

- End Pins

- Bridges & Tailpieces E-Guitar

- Bridges & Tailpieces

- Covers

- Pickguards / Scratch Plates

- Strap Locks

- Bridge Accessories / Spare Parts

- Screws, Nuts, Washers

- Neck Attachement

- String-Ferrules

- Jack plates

- Control Plates

- String Retainer / String Trees

- knobs (pots/switch)

- Relic Parts

- ... More

- Nuts & Saddles

- Fret Wire

- Pickups & Electronics

- Materials & Supplies

- How-to

- Guitar Making

Shop Startpage Guitar Making Techniques Tonewood Storage & Drying

Storage & Drying

On this site you will learn important about tonewood drying and storage.

As already explained, wood develops its good sound properties when the lowest possible mass is accompanied by the highest possible stiffness. If both factors (bulk density and modulus of elasticity) are at an optimum for a type of wood, this is normally also the best prerequisite for a high sound velocity, and this is what makes good tonewood, among other things.

However, since wood is a natural material, it is possible to exert a great deal of influence on the sound quality through proper handling, especially with regard to wood drying and storage.

Good tone wood must also be straight after drying. But if there were tensions in the trunk (e.g. at knots), these will now become apparent. The wood on my arm is no longer usable as tone wood.

The process of drying and storage begins with the removal of the moisture present both in the cells and in the cell walls. Once this has happened, a kind of "resinification" of the cell structures occurs. In the process, the cell structure gains in rigidity. The more gently the water is extracted, the more freely the water is removed and the less the cell structure becomes "clogged" and the cell structures can pass on sound.

Wood moisture:

Wood cells contain water both in their cellular spaces and in their walls, which is conducted to the consumers together with the nutrients dissolved in them. Wood moisture content is physically defined as the ratio between the mass of water contained in the wood sample and the mass of the absolutely water-free (kiln-dried) wood sample.

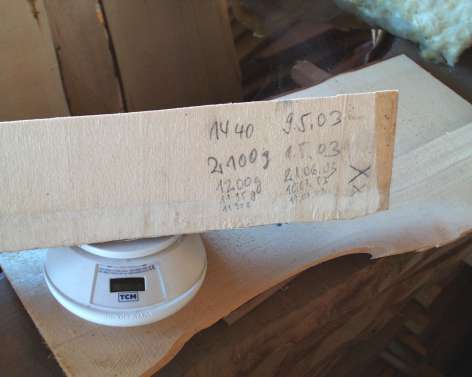

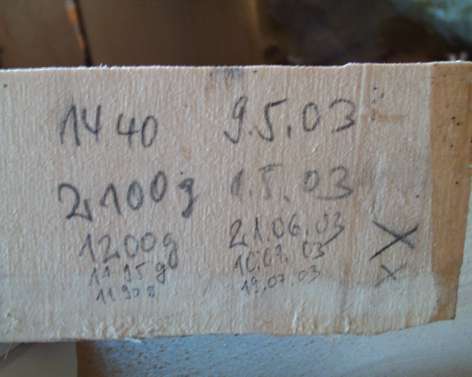

Thus, for example, one can weigh a "moist" sample, dry it to the point where there is no moisture left in the cells, and then weigh it again. If you now put the difference in weight before/after in relation to the "moist" initial mass, you now know your wood moisture content (in %). Checking the progress of drying with a scale is a simple and recognized method of tracking wood moisture over time.

The moisture contained in wood has an influence on:

- Wood density

- Wood Weight

- Strength properties (1% water absorption = 3 to 5% strength loss)

- Electrical Properties

I specifically followed the drying process. Here are a few photos about it.

Notes on the test piece

After more than three and a half months, an equilibrium had been reached between the wood and air humidity. The wood moisture had reached 12%. A rather low value, which was also influenced by optimal weather. Now it is time to move the wood indoors.

The following is an very interesting diagram. In it you can see that

- Spruce dries faster than Maple

- Spruce becomes air-dry after about 4 weeks

- Maple becomes air-dry after 6-8 weeks

If the process is right up to that point, natural decay processes such as rot, fungi or similar can still destroy the beautiful clay wood.

Stacking and storing

It is very important that the wood is stacked evenly. The stack must be such that the boards face some positional constraint. On top of the stack I put, for example, larger weights. A large tonewood dealer stacks his ceilings and floors this way, for example:

Quite freshly cut spruce scantlings and standing in the background to "run off" wood

Great spruce wedges!

Probably maple wedges with waxed ends.

|

Rall Guitars & Tools Hauptstrasse Tel +49 (0) 8803-48856-56 Retail Shop: By appointment only |

Subscribe our Newsletter By subscribing our newsletter you accept our Privacy Policy and Terms and Conditions. |