Tools, parts and what you need for guitarmaking

-

Tools & Jigs

-

Tools

- Fretting Tools (Base)

- Pliers

- Sanding Blocks

- Brushes

- Files

- Routers

- Routing Templates

- Templates / Straight Edges

- Fretting Templates - Fret Scale Templates

- Clamps

- Knives

- Measuring Tools

- Tool Sets

- Reamer

- Keys, Wrenches

- Drill Jigs

- Saws

- Drill Bits

- Scrapers

- Bending Irons

- Other Tools

- Fret Hammer

- Fret Pressing

- Fretboard Protector

- Fret Bender & Tang Nipper

- ... More

- Jigs for Luthiers

-

Tools

-

Hardware & Parts

- Necks & Bodies

- Tuners

-

Hardware / Parts

- Truss Rods

- Carbon / Titan Reinforcement

- Trussrod Nuts

- Washer for truss rods

- Bridge Pins

- End Pins

- Bridges & Tailpieces E-Guitar

- Bridges & Tailpieces

- Covers

- Pickguards / Scratch Plates

- Strap Locks

- Bridge Accessories / Spare Parts

- Screws, Nuts, Washers

- Neck Attachement

- String-Ferrules

- Jack plates

- Control Plates

- String Retainer / String Trees

- knobs (pots/switch)

- Relic Parts

- ... More

- Nuts & Saddles

- Fret Wire

- Pickups & Electronics

- Materials & Supplies

- How-to

- Guitar Making

Shop Startpage Guitar Making Tools Frame clamp

Frame clamp

Or how do I glue in places in guitar bodies that I can't get to by hand

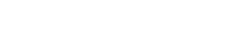

Anyone who has a size 11 glove, like me, knows how difficult it is to get through a sound hole into the inside of the guitar and then still do some work there. A special delicacy are cracks in solid sides. If the crack can be repaired with a little glue and some side clamps, there is no need to go inside. But if you want to strengthen the defect permanently, you need to add wood from the inside. This can be some wood veneer glued over the gap with strong magnets or individual pieces of wood (so-called "cleats") across the grain of the frame. And now the fun begins. In order to press the pieces of wood in a defined way and at the same time ensure the evenness of the frame, you can use so-called frame clamps. The trick is to pull a thin steel string (e.g. 0.09' electric guitar string) through a small hole in the crack area. On the inside of the body, the piece of wood is lined up with the steel string against the crack as if on a string of pearls. The force here comes from winding the string on the outside of the frame. I have described the exemplary repair in the repair section. Here I show how to make the ferrules.

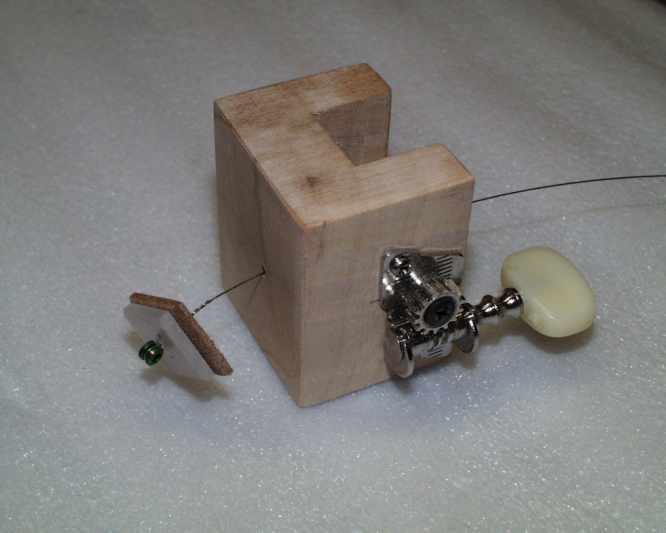

Take a clamp every 3-5cm on the crack. So with 3-4 clamps you are well served. The body consists of a block of hardwood (5x4x4cm) and a centered mechanism. The width of the groove depends on the available mechanics. This must be designed so that the shaft has some space to the bottom of the groove; the width results from the shaft length (shaft end should be approx. 4mm deep in the wood).

|

It is clever to plane out a piece of wood with a cross-section of 4x4cm, cut the groove with a router and fence, for example, and then cut the pieces to length. After drilling the shaft, you still need to drill a hole for the steel string. Depending on your taste, you can choose a position just below the shaft hole or just next to it (next to it gives more room for stringing and you can also place the string around the shaft several times first).

|

|

The inner piece of wood is pressed on evenly by means of a piece of plastic. Here is suitable, for example, Plexiglas or Teflon, which measures about 1.5x1.5cm and has a 2mm hole in the center. With a file you can almost touch two opposite sides. This has the sense that the piece of wood before threading e.g. with a small strip of double-sided tape on the plastic shim parallel to the direction of the wood. If you check the wood grain inside the guitar body during the gluing process, you only need to feel for the bevels and orient the piece of wood accordingly.

|

|

Before assembling the piece of wood is still sanded with sandpaper, I have the whole thing with linseed oil still let in. The underside of the clamping wood can be rubbed with a candle stub of kerosene or another type of wax, this prevents excess glue from sticking.

|

Here you can see three frame clamps and four glue screws on a frame crack.

|

Rall Guitars & Tools Hauptstrasse Tel +49 (0) 8803-48856-56 Retail Shop: By appointment only |

Subscribe our Newsletter By subscribing our newsletter you accept our Privacy Policy and Terms and Conditions. |